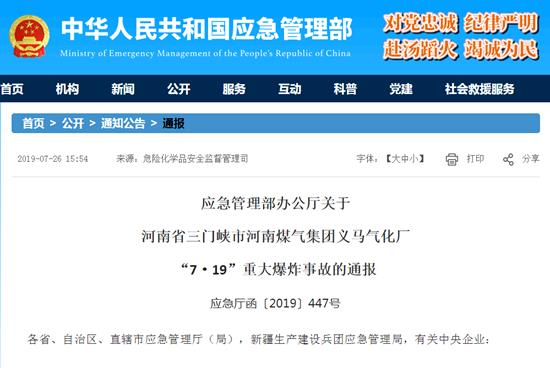

Management loopholes in the exposure of Yima accident caused by equipment "running with disease" for 24 days

Zhengzhou, People’s Daily Online, July 27 (Zhang Yili) A week after the "July 19" major explosion accident at Yima Gasification Plant of Henan Gas Group, the emergency management department issued a notice on the 26th, killing 15 people and seriously injuring 16 others. After preliminary investigation and analysis, the direct cause of the accident was that the leakage of the cold box of the air separation device was not handled in time, and a "sand explosion" occurred. The equipment leaked 24 days before the accident, but no attention was paid to the ultimate disaster.

24 days before the explosion, the leak still runs "sick"

According to the preliminary investigation and analysis, the direct cause of the accident was that the leakage of the cold box of the air separation unit was not handled in time, resulting in a "sand explosion" (a large amount of low-temperature liquid will be stored in the pearlescent sand in the insulation layer when the cold box leaks, and when the low-temperature liquid evaporates rapidly, the shell of the cold box will be cracked, and a large amount of pearlescent sand will be ejected with gas), which in turn led to the collapse of the cold box, resulting in the rupture of the nearby 500 cubic meters of liquid oxygen storage tank, the rapid leakage of a large amount of liquid oxygen, and the surrounding combustible materials will explode and burn under The specific cause of the accident is under further investigation.

According to the report, since the beginning of this year, there have been three major accidents in the chemical industry in China, namely "3 21" in Xiangshui, Jiangsu, "4 15" in Jinan, Shandong and "7 19" in Sanmenxia, Henan, which caused heavy casualties and bad influence, causing widespread concern in society.

The accident was caused by the air separation device in Yima Gasification Plant that failed to eliminate the hidden danger in time after the leakage and continued to operate with illness. On June 26, 2019, the purification branch of Yima Gasification Plant found that the oxygen content in the insulation layer of the cold box of C air separation unit increased, and it was judged that there was a small amount of oxygen leakage, but it did not attract enough attention, so it was considered that the monitoring operation was enough; On July 12, cracks appeared on the outer surface of the cold box, and the leakage volume further increased. Due to the imperfect equipment of the standby air separation system, the enterprise still insisted on "sick" production and failed to take timely measures to stop production and maintenance until the explosion accident occurred on July 19.

The Emergency Management Department requires all relevant enterprises in the country to seriously learn from the lessons of accidents, establish the concept of "hidden dangers are accidents", ensure that hidden dangers are eliminated as soon as they are discovered, and resolutely put an end to the operation of equipment with diseases. Local emergency management departments at all levels should strictly enforce the law and inspect, and if there are major hidden dangers such as the operation of equipment with diseases, they should be ordered to dispose of them immediately and be punished according to law.

Once advanced enterprises in production safety exposed management loopholes.

Yima Gasification Plant used to be an advanced enterprise in safety production. However, due to the loopholes in total factor safety management and the indifference of safety awareness and risk awareness of equipment and production, the management of equipment and other majors declined, which became an important cause of accidents. The accident also exposed some outstanding problems, such as unreasonable design and layout of the factory and insufficient attention to the safety production of supporting devices such as air separation.

The chemical production process is complex and the conditions are harsh. Most of the materials are flammable, explosive, toxic and harmful. In addition, the operating conditions such as high temperature, high pressure and low temperature all put forward strict requirements for the equipment. In daily production, process fluctuation, illegal operation, improper use and inadequate maintenance can cause equipment failure, lead to material leakage and lead to accidents.

According to the circular, strengthening equipment integrity management is the basis of chemical safety production, and all relevant enterprises should attach great importance to equipment professional management, optimize equipment design and selection from the source, and improve the intrinsic safety level. It is necessary to optimize the equipment and facilities with mature technology and good performance, master the safety information such as equipment design materials and operating parameters, and formulate strict technical regulations for equipment inspection and maintenance. It is necessary to increase the frequency of inspection and inspection of key parts, ensure that spare equipment is in good condition, earnestly carry out preventive maintenance, and eliminate hidden dangers in the bud.

By analogy, resolutely prevent and contain serious accidents.

According to the circular, after the accident, leading comrades in the State Council attached great importance to it and made important instructions, demanding that all efforts should be made to search and rescue personnel and treat the wounded, find out the cause of the accident as soon as possible, and deal with it seriously according to the law and regulations. At the same time, they deeply learned the lessons from the accident, made the safety supervision of hazardous chemicals enterprises the top priority, further investigated relevant safety hazards, and strictly prevented the occurrence of serious accidents.

In order to draw lessons from accidents, strengthen risk investigation and control by analogy, effectively implement the main responsibility of enterprises for safe production, further strengthen the work of safe production of dangerous chemicals, resolutely prevent and contain serious accidents, and fully safeguard the safety of people’s lives and property, the emergency management department requires that equipment and equipment should not run with diseases and carry out special inspections of air separation units. Strengthen the professional management of equipment, ensure the sound operation of equipment and the total factor management of chemical process safety, focus on the warning education of the main responsible persons of enterprises, conscientiously do a good job in the safety production of chemical and dangerous chemicals in the current high temperature season, and create a stable safety environment for the 70th anniversary of the founding of New China.

Incident scene